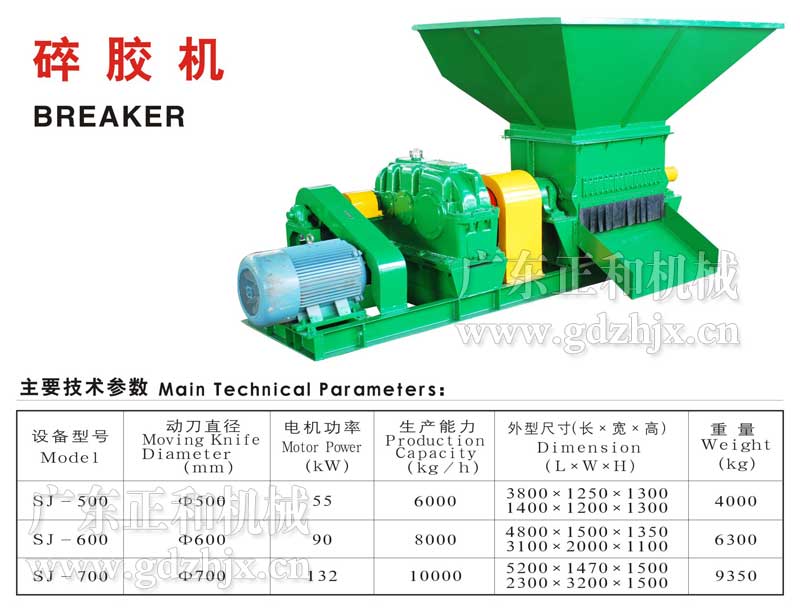

The rubber crusher is used in the primary processing of natural rubber to break and clean the mixed rubber and remove the sundries in the rubber. It is one of the main equipment for the production of no.20 standard rubber.

Rubber crusher is composed of body, knife shaft, moving knife, fixed knife, motor, reducer, hopper and so on.

Rubber pieces of rubber transmission is transition from motor to the shaft, then directly by the incoming transition shaft speed reducer drive the knife shaft rotation, on the knife shaft is equipped with the knife plate, and respectively before and after the body with a knife, when plastic piece from hopper loaded by the rotation of the knife dish will miscellaneous plastic piece broken, broken rubber after through the body of the inclined plate into the tank, so as to achieve the aim of crushing, washing.

[Use of rubber shredding machine]

Rubber crumb machine, also known as rubber crumb machine, rubber breaker, rubber breaker, rubber pellet shredder, rubber pellet pre-crusher

[Use of rubber shredding machine]

The rubber shredding machine is used in the initial processing of natural rubber to crush and clean the rubber to remove impurities in the rubber. It is an equipment for producing No. 20 standard rubber.

[Structure and working principle of rubber shredding machine]

The rubber crumb crusher is composed of a machine body, a cutter shaft, a moving knife, a fixed knife, a motor, a reducer, a hopper, etc.

The transmission of the rubber crumb machine is transmitted from the motor to the transition shaft, and then the transition shaft is transmitted to the reducer to directly drive the cutter shaft to rotate. The cutter shaft is equipped with a moving cutterhead, and fixed knives are installed at the front and rear of the machine body. After the blocks are loaded from the hopper, the rotating cutterhead breaks the miscellaneous rubber blocks into pieces. The broken rubber materials flow into the water tank through the inclined plate of the machine body to achieve the purpose of crushing and cleaning.

Rubber crushing machine model | SJ-50B |

Shredded rubber motorized cutterhead diameter | ф500mm |

Shredded rubber motorized cutterhead speed | 40r/min |

Rubber crusher reducer model | ZSY280-31.5-55II |

Rubber crusher reducer transmission ratio | 31.5 |

Rubber crusher motor model | Y250M-4 |

Rubber crusher motor power | 55KW |

Rubber shredding machine production capacity (dry glue) | 2000kg/h |

Rubber crushing machine, rubber crushing machine, rubber breaking machine

Sisal polishing cloth loom_Sisal fiber polishing cloth loom_Polishing cloth sisal loom_Sisal polishing cloth equipment_Sisal polishing cloth weaving machine_Automated sisal loom_Sisal polishing cloth production line

Sisal scraping machine_ Sisal scraping machine_ Automatic sisal scraping machine_ Sisal scraping equipment_ Sisal fiber scraping machine_ Sisal scraping machine_ Sisal scraping production line_ Fiber extraction and processing equipment_ Sisal processing equipment

Sisal carpet weaving machine_ sisal carpet machine_ carpet weaving machine_ sisal carpet machine_ sisal carpet weaving machine_ sisal fiber carpet weaving machine_ sisal carpet production equipment_ sisal carpet weaving machine_ Sisal carpet making machinery_ sisal processing equipment

Rubber odor exhaust gas treatment equipment, rubber odor exhaust gas treatment machinery, rubber processing odor exhaust gas treatment equipment, rubber processing plant odor exhaust gas treatment

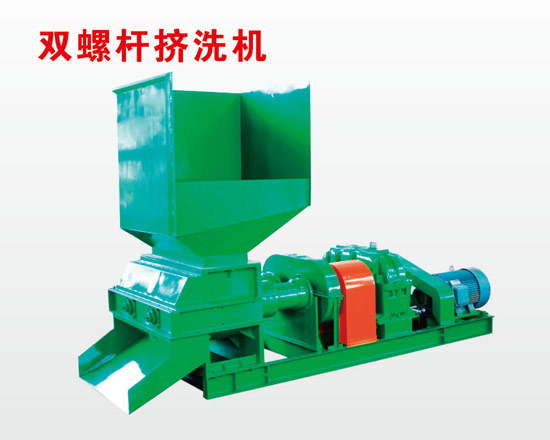

EXTRUDINE MACHINE

Unloading transport of sugarcane

Intermediate transfer card

Yun sugarcane trunk

Carpet loom

Polishing cloth loom

Squeegee production line

The dryer

Sugar cane pressing equipment

SET OF EQUIPMENT FOR SUGAR-CONE AUTO-UNLOADING CONVEYOR

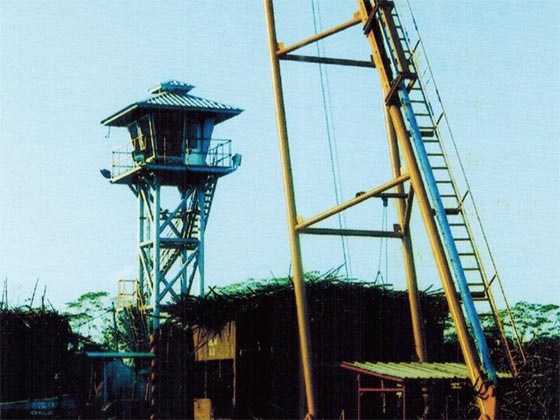

MAST TYPE SUHAR-CANE UNLOADER

Copyright © 8an.top